Wednesday, January 25, 2012

Tuesday, January 17, 2012

Admissions for NDT certification courses commensing on 18th February 2012

Trinity Institute of NDT Technology is leader in organizing and conducting world class nondestructive testing training, welding inspector training courses in India and Nigeria. NDT certification courses new batches commencing on 18th February 2012 at Trinity Institute of NDT Technology, Training center in Peenya Industrial Estate, Bangalore-India.

The certification methods to be organized are Ultrasonic testing(UT), Magnetic Particle testing(MPT), Liquid penetrant testing- PT (Dye penetrant inspection-DPT), Radiographic film Interpretation(RTFI) course and Visual testing(VT)/inspection courses.

All participants are requested to register for the courses by contacting the ' Course Director' on +91 98441 29439 / 99009 29439 or email your queries to: training@trinityndt.com. Log on to : www.trinityndt.com for more information.

The certification methods to be organized are Ultrasonic testing(UT), Magnetic Particle testing(MPT), Liquid penetrant testing- PT (Dye penetrant inspection-DPT), Radiographic film Interpretation(RTFI) course and Visual testing(VT)/inspection courses.

All participants are requested to register for the courses by contacting the ' Course Director' on +91 98441 29439 / 99009 29439 or email your queries to: training@trinityndt.com. Log on to : www.trinityndt.com for more information.

Trinity NDT is now suppliers of NDT equipments of Ferrochem Make

Trinity NDT is a supplier of NDT equipments, accessories and consumables in India. Trinity NDT is appointed as Stockist and dealer for 'Ferrochem' make MPT equipments & DPT materials.

Ferrochem NDT systems Pvt Ltd is a reputed manufacturer of MPT powders, pastes, inks, DPT materials, equipments, accessories and consumables since 1977 in India. Many of the MPI chemicals, powers, dye penetrant chemicals and materials are approved by FIEO, MCCIA, NPCIL, India, ARDE, Pune, BHEL, Thiruchurapalli, Hyderabad, Goindwal, DGAQA, New Delhi, DMRL, Hyderabad, GRSE, Kolkata, GTRE, Bangalore, HEMRL, Pune, NSIC, ICF, Chennai .

For more information, enquiries about supplies, quotes email to : sales@trinityndt.com or call 'Sales Manager' on +91 98441 29439, 99009 29439, +91-80-28366466

For more info visit: www.trinityndt.com

Ferrochem NDT systems Pvt Ltd is a reputed manufacturer of MPT powders, pastes, inks, DPT materials, equipments, accessories and consumables since 1977 in India. Many of the MPI chemicals, powers, dye penetrant chemicals and materials are approved by FIEO, MCCIA, NPCIL, India, ARDE, Pune, BHEL, Thiruchurapalli, Hyderabad, Goindwal, DGAQA, New Delhi, DMRL, Hyderabad, GRSE, Kolkata, GTRE, Bangalore, HEMRL, Pune, NSIC, ICF, Chennai .

For more information, enquiries about supplies, quotes email to : sales@trinityndt.com or call 'Sales Manager' on +91 98441 29439, 99009 29439, +91-80-28366466

For more info visit: www.trinityndt.com

Saturday, January 14, 2012

Saturday, January 7, 2012

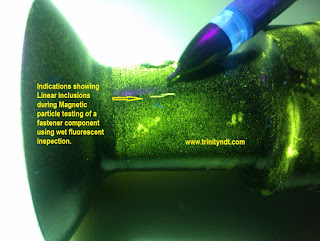

Magnetic particle, Dye penetrant chemicals NDT Equipment for sale

'Trinity NDT' now has launched the facilities for sales, calibration and servicing of all types of NDT equipments, most significantly complete range of Magnetic particle equipments, yokes, stationary machines, consumables, test blocks and dye penetrant materials/chemicals supplies suitable for wide range of applications including quality control inspection companies related to precision component manufacturing, fabrication weld joints inspections, automobile, pressure vessel, boiler components, aerospace components manufacturing, petroleum refineries and defense establishments.

The following is the brief list of NDT equipments, accessories and consumables available with Trinity NDT in India.

1. Liquid penetrant chemicals

a. Visible, fluorescent dye penetrant chemicals including water washable, solvent removable

b. Cleaners/solvent for liquid penetrant testing applications

c. Hydrophilic and lipophilic emulsifiers

d. Dry, wet developers

2. Equipment for dye/liquid penetrant inspection

3. Fluorescent dye penetrant systems as per customer specific requirements in automobile, aerospace, railways and other engineering applications

4. Complete range of liquid penetrant testing accessories meeting with both national and international standards

5. Ultraviolet(UV) lights for dye penetrant and magnetic particle testing applications

6. UV/light intensity meters

7. TAM panels

8. Nickel, chrome test panels

9. Aluminium comparator blocks

10. Ultraviolet light goggles for ndt applications

11. Miniscus test kits

12. Lint fee cloths

13. Magnetic particle testing powders suitable for ASME BPVC code confirming pressure vessel manufacturing industries & meeting the requirements of other international standards

14. White contrast paint for magnetic particle crack checking applications

15. Suppliers and dealers of complete range of magnetic particle inspection equipments, accessories, consumables including residual field indicators, pie gauges, centrifuge tubes, ketos rings, copper mesh pads for wet horizontal stationery type equipments, electromagnetic yokes, prods and coils

16. Calibration of yoke type, prod type, horizontal stationery type equipments, accessories including ammeters

For more details about complete range of ndt equipments, magnetic particle equipments, dye penetrant chemicals and other ndt accessories please mail your requirements to: sales@trinityndt.com or contact 'Sales Manager' on +91 98441 29439 / 99009 29439 / +91- 80- 283 66466

The following is the brief list of NDT equipments, accessories and consumables available with Trinity NDT in India.

1. Liquid penetrant chemicals

a. Visible, fluorescent dye penetrant chemicals including water washable, solvent removable

b. Cleaners/solvent for liquid penetrant testing applications

c. Hydrophilic and lipophilic emulsifiers

d. Dry, wet developers

2. Equipment for dye/liquid penetrant inspection

3. Fluorescent dye penetrant systems as per customer specific requirements in automobile, aerospace, railways and other engineering applications

4. Complete range of liquid penetrant testing accessories meeting with both national and international standards

5. Ultraviolet(UV) lights for dye penetrant and magnetic particle testing applications

6. UV/light intensity meters

7. TAM panels

8. Nickel, chrome test panels

9. Aluminium comparator blocks

10. Ultraviolet light goggles for ndt applications

11. Miniscus test kits

12. Lint fee cloths

13. Magnetic particle testing powders suitable for ASME BPVC code confirming pressure vessel manufacturing industries & meeting the requirements of other international standards

14. White contrast paint for magnetic particle crack checking applications

15. Suppliers and dealers of complete range of magnetic particle inspection equipments, accessories, consumables including residual field indicators, pie gauges, centrifuge tubes, ketos rings, copper mesh pads for wet horizontal stationery type equipments, electromagnetic yokes, prods and coils

16. Calibration of yoke type, prod type, horizontal stationery type equipments, accessories including ammeters

For more details about complete range of ndt equipments, magnetic particle equipments, dye penetrant chemicals and other ndt accessories please mail your requirements to: sales@trinityndt.com or contact 'Sales Manager' on +91 98441 29439 / 99009 29439 / +91- 80- 283 66466

Tuesday, January 3, 2012

Workshop on Failure Mode and Effect Analysis in Bangalore, India

BACK GROUND

In today's competitive market environment, the industry has realized the fact that servicing unreliable products is a very costly proposition. To a large extent, reliability is built into the product during the design and development phase.

Failure Mode & Effects Analysis (FMEA) is an essential ingredient of reliability engineering and is a very powerful and effective technique used for improvement in design, assembly, materials engineering, servicing etc., in a diverse range of manufacturing activities. FMEA can be effectively applied in case of new developments, new technologies and components/assemblies or products which have inherent problems showing up in practice.

'Failure Mode & Effects Analysis' (FMEA) is an “ error prevention” oriented and proactive methodology that tries to pre-empt the occurrence of errors; reduce their significance ( even if they were bound to occur ) and in unavoidable circumstances, to increase the chance of error detection, so that the process could then be suitably controlled. FMEA is an aid for continuous improvement which fits into a PDCA (Plan-Do-Check-Act) pattern of activity. Whenever changes in product or processes or vendor / supplier are envisaged or effected, FMEA is redone to evaluate their effects.

Recognizing this need, IMTMA is organizing a two day interactive Workshop on 'Failure Mode & Effects Analysis' (FMEA), on 23 - 24 January 2012 at Bangalore, India.

Failure Mode & Effects Analysis (FMEA) is an essential ingredient of reliability engineering and is a very powerful and effective technique used for improvement in design, assembly, materials engineering, servicing etc., in a diverse range of manufacturing activities. FMEA can be effectively applied in case of new developments, new technologies and components/assemblies or products which have inherent problems showing up in practice.

'Failure Mode & Effects Analysis' (FMEA) is an “ error prevention” oriented and proactive methodology that tries to pre-empt the occurrence of errors; reduce their significance ( even if they were bound to occur ) and in unavoidable circumstances, to increase the chance of error detection, so that the process could then be suitably controlled. FMEA is an aid for continuous improvement which fits into a PDCA (Plan-Do-Check-Act) pattern of activity. Whenever changes in product or processes or vendor / supplier are envisaged or effected, FMEA is redone to evaluate their effects.

Recognizing this need, IMTMA is organizing a two day interactive Workshop on 'Failure Mode & Effects Analysis' (FMEA), on 23 - 24 January 2012 at Bangalore, India.

OBJECTIVES

This workshop would help participants to :

- Develop a systematic approach in understanding the potential problems, in design and planning stage itself, thereby avoiding costly and time consuming post – error corrective actions.

- Understanding the FMEA methodology and give background information on how to organize FMEA groups and fosters a team-work culture of cross-functional nature in developmental activities which is very essential for enhancing the reliability of complex designs and process.

- Highlight the important aspects of FMEA through group interaction exercises on Design and Process FMEA with specific examples.WORKSHOP METHODOLOGYThere will be a combination of lecture sessions with case study presentations and specific simulation examples. The participants will get an intensive exposure on FMEA with active involvement in problem solving, through group exercises. The workshop will be highly interactive where participants can raise questions and solicit feedback from the faculty.FACULTYThe workshop will be conducted by Mr. M. C. Ramakrishnan, Former Vice President - Quality, Bosch Limited. Mr. M. C. Ramakrishnan is an industry expert with over 37 years of experience in the field of quality tools like Six Sigma, SPC, MSA, Poka - Yoke etc. He is a trained Six Sigma Black Belt and championed number of projects at Bosch.PARTICIPANTS PROFILEThis workshop will benefit practicing engineers and senior technical personnel involved in the functions of Design and Development, Process Planning, Product Engineering, Application engineering, Quality Assurance, R&D, Manufacturing, Servicing etc., and other related areas from Machine Tool, Automobile & auto ancillaries, Tool rooms, Defence and Railway establishments, General Engineering and other Capital goods manufacturing industries. In order that the participation is effective and beneficial, it is recommended that participating companies depute a multi-disciplinary team of 2 or 3 people from the above functions. Participants should have knowledge of related products and processes.For Nomination & Enquiries call :

Mr.Rohith Ragav

E-mail : rohith@imtma.inWebsite : www.imtma.in

Coming Soon International Conferences on NDT

2012 June 11-14, Italy Naples

Abstract deadline 15. January 2012

11th Quantitative InfraRed Thermography

http://www.qirt2012.unina.it/ocs/index.php/2012/QIRT

2012 Sep 19-21, Austria Wels

Abstract deadline 31. January 2012

International Conference on Industrial Computed Tomography

Organizer: Research Group Computed Tomography

http://www.3dct.at/cms/index.php?option=com_content&view=article&id=114&Itemid=112&lang=en

2012 Jun 18-20, Canada, Toronto

Abstract deadline 29. February 2012

4th International CANDU In-service Inspection and NDT in Canada 2012 Conference

Organizer: Canadian Institute for NDE (CINDE)

http://events.cinde.ca/

2012 Sep 12-15, Spain, Granada

Abstract deadline 15. March 2012

30th European & 7th International Conference on Acoustic Emission Testing

Organizer: University of Granada

http://www.2012.ewgae.eu/

Subscribe to:

Comments (Atom)